AI Knowledge Capture for Manufacturing

Stop the Knowledge Walkout

What Is the Knowledge Walkout in Manufacturing?

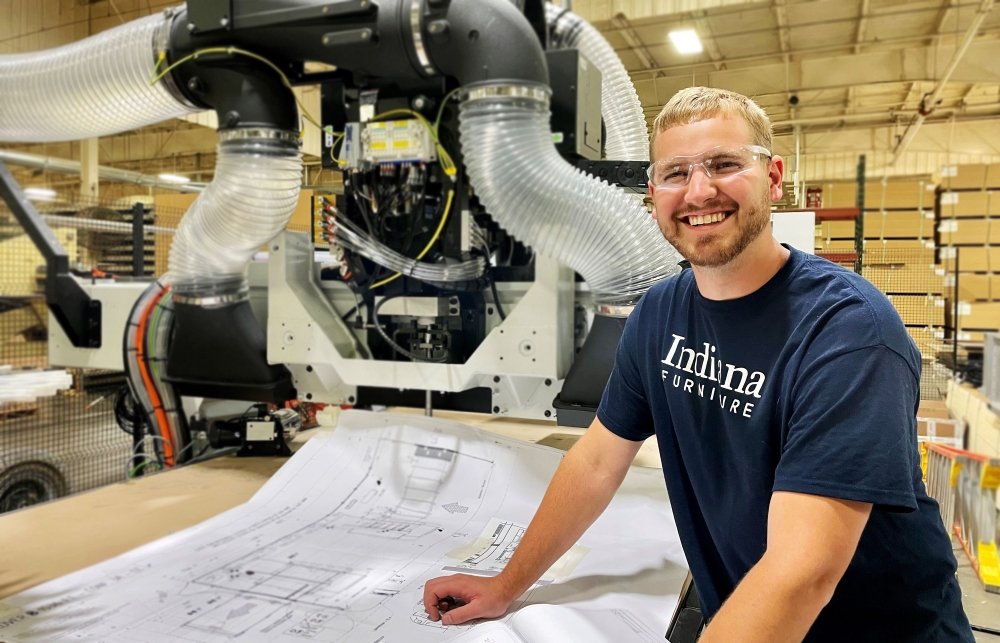

Manufacturers are experiencing unprecedented knowledge loss as seasoned operators retire. When tacit knowledge leaves with them, companies lose the know-how that prevents downtime, protects quality, and keeps new operators productive. The result is higher costs and greater risk across every shift.

How Murray Mentor Prevents Knowledge Loss in Manufacturing

Murray is an AI-powered voice assistant built for factory environments. It preserves expertise before it walks out the door and delivers it instantly to frontline workers.

Key benefits:

Capture tacit knowledge before it’s gone → Build a living knowledge base that can be used to help newer workers.

Real-time guidance for workers → Voice-enabled mentoring on the job.

Faster onboarding → New hires get trusted answers without waiting for busy experts.

Quality and uptime protection → Reduce variation, rework, and downtime.

Business Impact and ROI for Manufacturers

Even modest improvements in uptime, training efficiency, and quality deliver measurable financial results.

Maintaining uptime

Real-time, voice-enabled guidance speeds issue resolution.

Reducing ramp-up time

New operators become floor-ready faster, with fewer dependencies.

Improving consistency

Best practices captured from senior workers reduce variation and costly mistakes.

Preserving expertise

Retiring employees leave behind a living knowledge base that strengthens resilience.

Schedule a Demo of Murray Mentor

Stop the Knowledge Walkout

Every retirement takes decades of expertise with it. Don’t let knowledge loss put your operations at risk.

Blog & News

FAQs on Knowledge Loss in Manufacturing

Is Murray just another chatbot?

No. Murray is purpose-built for manufacturing. It combines domain expertise and the knowledge of your experts accurate, trusted guidance.

What happens when manufacturers don’t capture knowledge before employees retire?

The result is longer downtime, inconsistent execution across shifts, and costly mistakes that impact customers and profitability. Over time, the Knowledge Walkout compounds into lost competitiveness.

How are manufacturers currently trying to address knowledge loss?

Most rely on shadowing, paper manuals, or basic training programs. These are limited—they don’t scale, and they don’t preserve the why behind expert decisions. And until now, AI-powered solutions have focused only on written documentation, which fails to capture the most critical knowledge — tacit knowledge — that keeps operations running.

How can Murray help with the manufacturing skills gap?

Murray can capture, organize, and deliver expertise in real time. Instead of losing knowledge when employees leave, manufacturers create a living, evolving knowledge base that’s available on demand to every operator.

Who benefits most from solving knowledge loss—sometimes called the ‘knowledge walkout’?

Everyone in the organization gains. Executives see greater resilience and fewer costly disruptions. Seasoned experts spend less time answering routine questions and more time solving unique problems. And the newer generation workers solve problems faster, building confidence on the floor.